Induction Heating for Electric Vehicles

Quality EV Cars One Part at a Time

For 60 years Inductoheat has provided induction heating systems to OEM automotive manufacturers and tier suppliers to make components better. We have been at the forefront of induction technology and continue to develop the most specialized and robust induction thermal processes for the traditional automobile.

While internal combustion powered vehicles will be part of the automotive landscape for decades to come, Inductoheat is committed to adapting and adopting new induction heating technologies for what the automotive market will bring. With the advent of electric vehicles, we see a changing industry and an exciting opportunity to bring advanced induction technologies to those new to the automotive space.

Although the structure and drive mechanisms of an electric vehicle differ from conventional internal combustion platforms, there are other differences that must be considered when looking at EV components. Electric vehicles produce instant and much higher torque over internal combustion vehicles when accelerating or changing speed. Because of this, powertrain components such as gears, shafts, and joints must be strengthened to withstand the additional load and stresses. Induction heating can properly address this requirement by ensuring superior strength and improving other mechanical characteristics over alternative methods such as carburization. For example, induction heating offers appropriate case depths, less distortion, and exceptional repeatability as it is a single piece processing technology.

There are also many other automotive applications from bumper to bumper, that can be completed more effectively by utilizing induction heating over other methods.

Induction Heating for Electric Vehicles: Applications

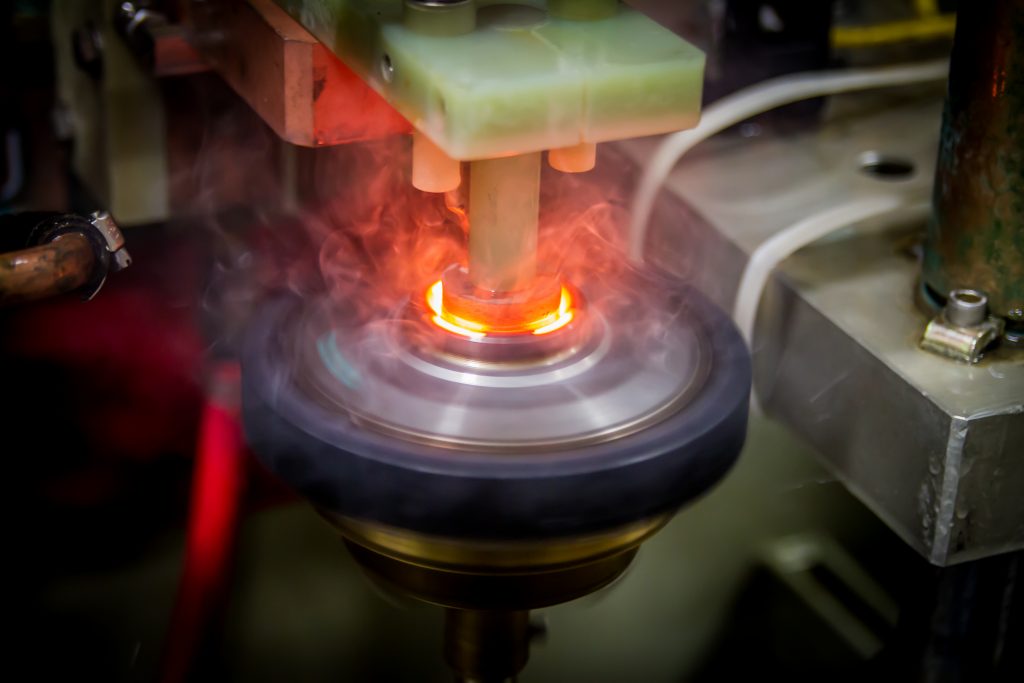

Induction Hardening

- Main shafts

- Constant velocity joints

- Steering rack

- Steering gears

- Pinion gears

- Ring gears

- Shock rods

- Tie rods

- Door impact beams

- Hubs

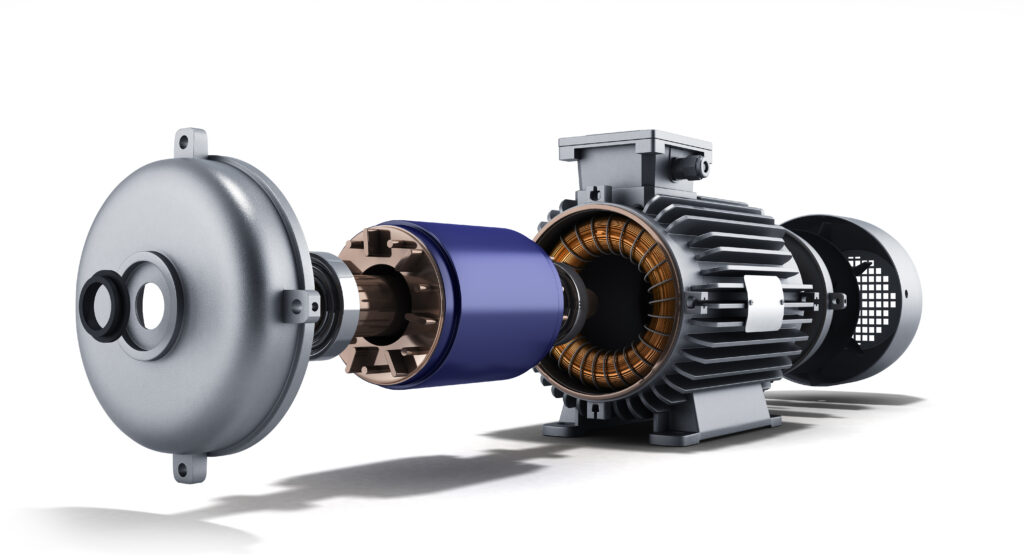

Induction Shrink Fitting

- Bearings

- Shafts

- Rotors

- Housings

- Pulleys

- Stators

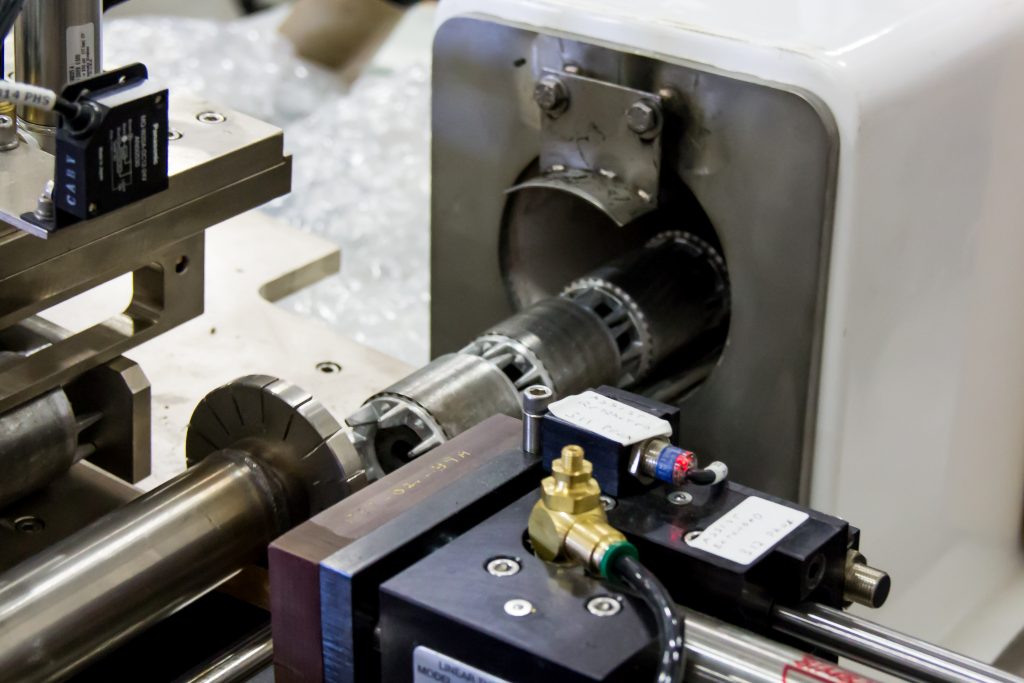

Induction Rotor Curing

- Varnish

- Wax

- Paint

- Powder coat

When the scope of induction heating for electric vehicles becomes extremely broad, Inductoheat makes use of computer simulation. Computer modeling and FEA simulation is a powerful tool used by our engineers and scientists to investigate or design a physical system and/or process using a virtual mathematical model. This simulation provides a quantitative approach to designing and developing induction heating processes, allowing complex physical phenomena that cannot be clearly observed and/or measured.

We continue to embrace breakthrough technologies and manufacture the most robust induction heating systems for the Electric Vehicle Market.