Services

Process Development Laboratory

Inductoheat’s in-house Metallurgical Laboratory and Process Development Departments provide expertise on the development of induction heating and heat treatment for ferrous and non-ferrous-based alloys to improve product life.

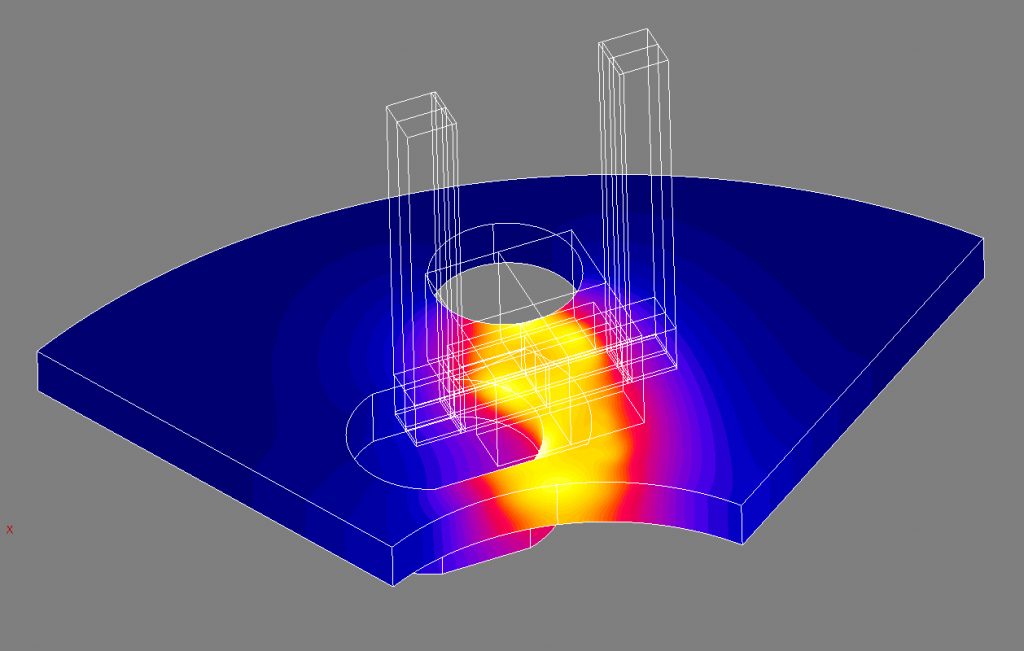

Computer Modeling – Induction Simulation

Inductoheat’s induction simulation specialists can solve everyday challenges in induction using computer modeling. Using electromagnetic and thermal analysis, we are able to predict how a part, tooling or specific application will respond to the induction process.

24 Hour Service & Support

Inductoheat’s field service team offers the industry’s highest level of technical support and service for when you need it the most. Fast! Customers benefit from our highly skilled on-site field service engineers and our 24/7 technical support…

Preventative Maintenance

Your Inductoheat equipment requires periodic checks and maintenance procedures which help to ensure that it is operating safely, reliably and with optimum efficiency. Our team of experienced field service engineers is equipped with years of industry knowledge and state of the art analysis tools. Inductoheat offers full service maintenance plans designed to extend the life of your induction equipment.

Aftermarket Spare Parts

Inductoheat maintains a stock inventory of thousands of difficult to find and long lead time components. Parts are available for both our induction power units and our machines.

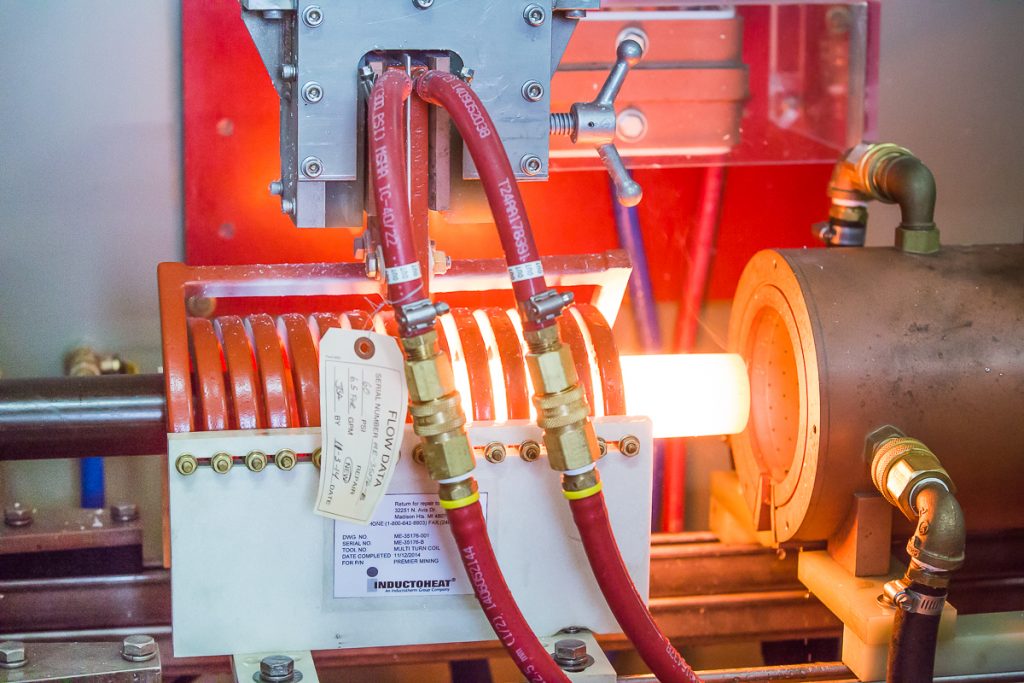

Induction Coil Repair

We’re experts in inductor repair of simple fabricated designs to complex induction coils, including forge coils.

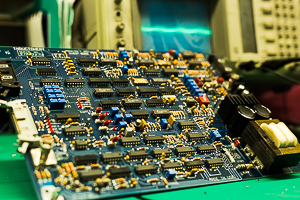

Induction Power Supply Technical Seminars

Inductoheat’s technical seminars are held in our state-of-the-art training facility in Madison Heights Michigan. We cover diagnostic techniques and component replacement procedures, so your personnel can efficiently troubleshoot and perform preventative maintenance on your induction equipment